In high-temperature environments, choosing the right refractory anchor shapes directly impacts lining longevity, thermal stability, and maintenance costs. Among the most commonly specified designs are V anchors vs Y anchors, along with specialty corrugated anchors used in demanding applications.

If you’re engineering or maintaining furnaces, kilns, heaters, incinerators, or FCC units, understanding the differences between these refractory anchor shapes will help you select the right solution for performance and durability.

Refractory anchor shapes are metallic components welded to vessel shells or structural steel to secure refractory linings in high-heat environments. Their design influences:

Common refractory anchor shapes include:

Each shape serves a specific structural and thermal function.

When comparing V anchors vs Y anchors, the primary differences lie in geometry, load handling, and refractory retention behavior.

V anchors are bent into a “V” shape and are commonly used in castable refractory applications.

V anchors are widely specified due to their balance of cost, performance, and ease of fabrication.

Y anchors feature a central stem with two outward legs, forming a Y configuration. They are designed to provide superior load distribution in thicker refractory linings.

When evaluating V anchors vs Y anchors, Y anchors are typically preferred in heavy-duty, high-heat environments.

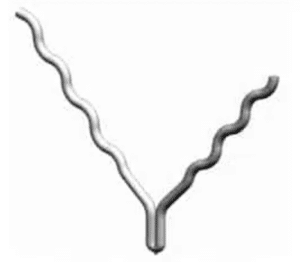

Corrugated anchors feature a wave-like or zig-zag pattern that increases flexibility and mechanical bonding.

Corrugated anchors are often used in:

For certain designs, corrugated anchors outperform traditional V anchors or Y anchors due to their ability to absorb movement without compromising lining integrity.

V Anchors vs Y Anchors vs Corrugated Anchors: Quick Comparison

| Feature | V Anchors | Y Anchors | Corrugated Anchors |

| Best For | Moderate thickness | Heavy linings | Thin linings |

| Load Distribution | Moderate | High | Moderate |

| Thermal Flexibility | Good | Very Good | Excellent |

| Refractory Retention | Strong | Very Strong | Strong |

| Cost | Lower | Moderate | Moderate |

Selecting between V anchors vs Y anchors or specifying corrugated anchors depends on:

In general:

Understanding the differences between V anchors vs Y anchors and other refractory anchor shapes like corrugated anchors is essential for optimizing refractory performance and minimizing costly shutdowns.

The right anchor design improves:

If you’re designing or maintaining a high-temperature system, specifying the proper refractory anchor shape is just as important as selecting the correct refractory material.

Get expert guidance on selecting the right refractory anchor shapes for your project.